Monitoring for wind turbine generator systems

Optimisation of maintenance and service thanks to lightning current measurement.

DEHNdetect is a lightning current measuring system that records both cloud-to-earth flashes and upward flashes. This condition monitoring system specifically for wind turbines transmits lightning data in real time and facilitates the optimisation of maintenance and service operations.

Learn about the DEHNdetect lightning current measuring system and increase the availability of wind turbines.

- Real-time information

- Optimised maintenance and service operations

- Reduced downtimes

- Optimised system cost efficiency

Why is lightning current measurement needed for wind power systems?

Lightning damage to wind turbines – both onshore and offshore – often goes unrecognised, as it frequently does not cause immediate failure of the system. In the case of upward flashes, the initial long stroke current of only a few 100 A is the main cause of damage, such as melting on the receptors of the rotor blades. Damage like this must be recognised and rectified, as it can lead to system failure in the long term.

Condition monitoring for wind power systems

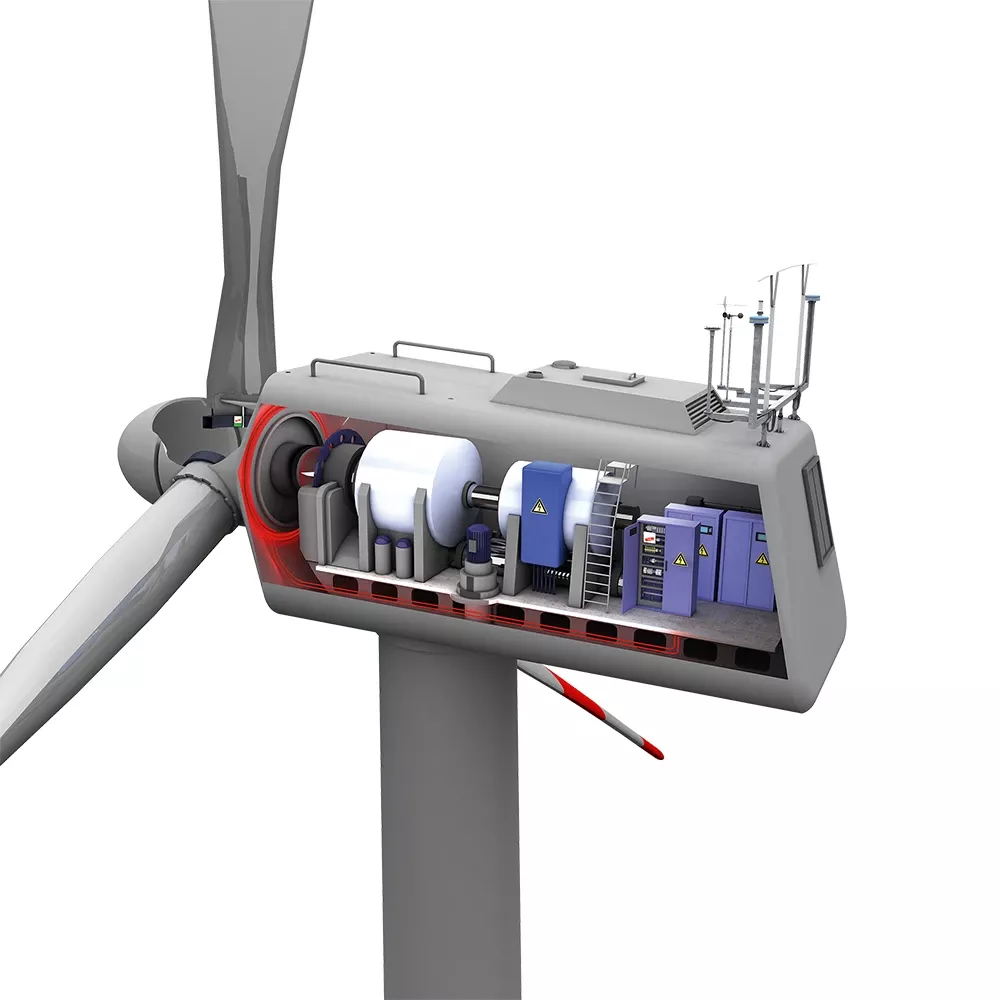

To determine the intensity of lightning strikes, the IEC 61400-24 standard recommends the installation of measuring systems that also record long stroke currents. Keep a watchful eye on the parameters of a lightning event with DEHNdetect. This lightning current measuring system can be installed either at the base of the tower or at the transitions from nacelle to tower or hub to nacelle. It records both long stroke and impulse currents and automatically sends a notification after a lightning event.

The blade detection feature indicates which rotor blade is affected, among other things. This means that maintenance work can be planned and optimally prepared on the basis of detailed data.

Practical data management

The data are transmitted to a cloud via a mobile phone connection or via the wind turbine's local network. All the integrated lightning current measuring systems can be displayed individually here, and the parameters can be read out and managed. The option of connecting to various monitoring systems also safeguards flexible use in the future. Alternatively, data can be transmitted to a company's own servers.

The system records the following lightning current parameters:

- Impulse current [kA]

- Long stroke current [A]

- Charge [C]

- Specific energy [MJ/Ω]

- Rise time [kA/μs]

Lightning information services cannot measure upward flashes, known as ICC-only events, which are critical for wind turbines. This is where DEHNdetect comes into its own, as it also detects upward flashes – a clear advantage when documenting damage for insurance companies.

Features of the DEHNdetect lightning current measuring system

- Real-time information on lightning events

- Optimisation of maintenance and service operations

- Prevention of subsequent damage

- Reduction of downtimes

- Increased wind turbine service life

- Optimisation of overall system cost efficiency

The measuring system components

We will be happy to clear these up in person.

Relevant standards for lightning protection in wind turbine systems

IEC 61400-24 deals with the topic of lightning protection for wind turbines and contains detailed information on the selection of protection components. The installation of measuring systems that also record long stroke currents is recommended.

Downloads

Lightning Protection Solutions for Wind Turbines

Firmware update

Configuration file

DEHNdetect

DEHNdetect retrofit

Berlin TV tower – Analysis of lightning events

FAQs

- The blade detection units are installed above the down conductor in each blade root using a two-component adhesive.

- The data logger and Rogowski coil are inside the nacelle: The data logger is installed in one of the switch cabinets and the Rogowski coil is mounted at the entrance from hub to nacelle or around the yaw system.

No, blade detection units communicate with the data logger wirelessly via ZigBee.

The blade detection units have a built-in battery that will last for about five years. Consequently, no external power supply is needed.

Yes, the battery can be replaced. A new battery is readily available on the market.

It is connected using a coaxial shielded cable with a max length of 15 m.

- Peak amplitude

- Charge value

- Specific energy

- Maximum rise time

- Complete waveform at 4 MHz

- Time stamp and duration

Yes, the polarity is measured. This is visible with the minus or plus sign for the peak amplitude and it is also visible in the waveform.

There are 3 possibilities:

- Modbus TCP communication which can be used to send all data to the wind turbine's local SCADA system

- Ethernet connection (MQTT protocol) and then into the internet via a router

- Via an LTE inbuilt modem (MQTT protocol) if the wind park is covered by a mobile network.

Yes, that is possible with the basic version. It comprises the blade detection units and the data logger.

The full version with an additional Rogowski coil allows accurate measurement of the whole event.

The system can be upgraded from the basic to the full version at any time.

No, the system can also work without blade detection units and the user will still receive measured values.

However, the measuring system can also be used with blade detection units only and without a Rogowski coil. In this case, the information provided includes which blade was struck, the time stamp and two threshold values for the peak current: the event was above 100 A and below 5 kA, or the event was above 5 kA

There are two options for this:

- A self-test which shows whether the integrator of the Rogowski coil is working properly.

- A manually triggered measurement, whereby the values obtained show whether the system is online and able to measure events.

Upward flashes are the main cause for material melting. The more frequently a component, for instance, a rotor blade receptor, is hit by an upward flash, the more material is worn away over time. The damage therefore increases very gradually and often goes unnoticed. This can lead to expensive system downtimes in the long run.

The system has been designed for installation in both new and older wind turbines.

Yes, because the system records lightning events over a very wide range and with an accuracy of +/-5% of the measured value.

No, but it does recommend systems like this so that operators can obtain reliable information concerning a lightning event. This information can be used for maintenance planning, among other things.

A lightning current measuring system should be capable of measuring initial long stroke currents which are not characterized by the peak amplitude but by the charge value – this means that charge values should also be provided.

Yes. Even if the lightning event only has a low current of a few 100 A, the charge value can still be correspondingly high due to the long duration. The charge causes melting at the receptors.

In addition, small current of only a few 10s of kA can have negative effects on the carbon fibre parts inside the blade if the slope (rise time) of such an event is very high.

Modern wind turbines can be as high as 200 metres. As a result, they trigger upward flashes - often purely ICC-only. Long stroke current has a low current value, but it lasts for a very long period of time. As a result, this type of lightning event often causes serious damage.

The reason for this is the high electric charge. It is the main cause of material melt out and erosion at the arc base. The more frequently a component, for instance, a rotor blade receptor, is hit by an upward flash, the more material is worn away over time. Damage therefore often develops unnoticed and can lead to expensive system downtimes in the long run.

Services

We can provide support for your project from the planning to the implementation and beyond. Take advantage of our wide range of practical tools and services.

Any questions?

What other topics are of interest to you?

Just select them and read on.