Periodic inspections of protective and auxiliary equipment

Periodic inspections are essential for the safety of persons and systems and are defined by law and standards in various specifications. Regular testing of electrical test equipment is not only a duty, however. Those who comply with and conduct them benefit from doing so. Tested equipment protects lives, keeps systems running and ensures more efficient operations.

Note: No prior registration required! Simply submit, see below for more information.

This is why periodic inspections are important:

Safety of people

Defective or improperly functioning test equipment can pose a risk to the user. Regular tests therefore help to avoid accidents and damage.

Legal regulations and standards

The "EN 61243-1 – Live working – Voltage detectors" standard specifies requirements for voltage detector of capacitive type for testing the absence of voltage in electrical installations. When used correctly, such voltage detectors are used to check the absence of voltage in an electrical system.

"EN 61230 – Live working - Portable earthing and short-circuiting devices" specifies requirements for portable devices for earthing and short-circuiting electrical equipment. When used correctly, such devices ensure that an electrical system is and remains de-energised while working on it.

Prevention of downtimes and production stoppages

Early detection of defects helps prevent unexpected operational disruptions. In addition, the useful life of the test equipment is extended and costs for new purchases are reduced.

Insurance cover and liability

Without proof of regular tests, the insurance cover may be invalidated. In the event of damage, the operator is liable if no testing in accordance with the regulations can be proven.

Periodic inspections of voltage detectors

Work on electrical systems is always guided by the 5 safety rules. Do not take any risk for your team and have the test equipment in use checked regularly.

Our audit services include:

- Visual inspection

- Manual testing

- Measurement

- Measurement of the discharge current

- Testing the protection against bridging

- Testing for clear indication

We will explain below how to send us your devices.

Periodic inspections of EaS devices

The earthing and short-circuiting (EaS) device ensures that the system is in a voltage-free state for the duration of the work. Make sure you keep the regular inspection intervals for earthing and short-circuiting devices.

What the standard says:

Earthing and short-circuiting devices according to EN 61230 are safety devices and are subject to the requirements of periodic inspections.

Untested, defective earthing and short-circuiting devices are a high safety risk in the experience of the employers' liability insurance association. Tests are required in accordance with EN 50110-1 for safety when working on electrical systems.

Supplement 1, paragraph 4.2

It describes maintenance tests (regular inspection with a non-destructive, multi-stage procedure (LoRe measuring method), which detect possible internal cable damage without destroying the EaS device.

More information can be found in the download area.

Testing of EaS devices – your possibilities

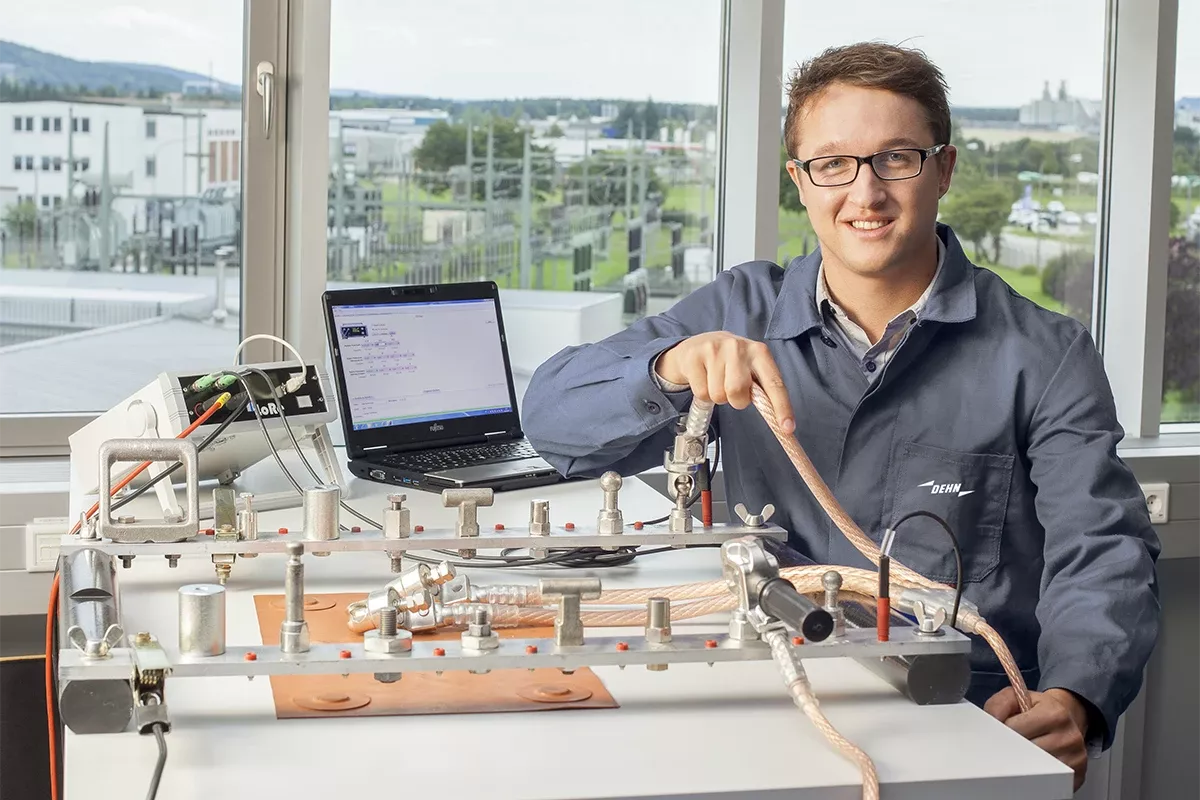

Testing at DEHN

Send us your EaS devices and we will check they are in perfect condition. The scope: visual inspection, static and dynamic testing.

The price of the periodic inspection depends on the type of device in question; inquiries to [email protected].

Check for yourself

With the MikroΩmeter Lore EaS, you can inspect EaS devices non-destructively and, if necessary, detect hidden damage that cannot be detected by visual inspection alone.

How to send us your devices

You do NOT need to register your devices in advance for the test.

The periodic inspection of your devices is carried out at our Neumarkt location.

To ensure a smooth process, please note the following procedure:

Labelling the goods shipment

For clear identification of your consignment, please always enclose an accompanying letter in the form of a purchase order or similar. This accompanying letter should include the recipient of the service with the VAT ID and the recipient of the goods and invoice, each with the full address. If available, please also state the offer number.

Please understand that for unmarked or unassignable shipments, the throughput times will be extended.

ATTENTION: Devices packaged in foil only will not be accepted!

Choose secure packaging for shipping.

We use special packaging for the return shipment due to insurance policy reasons. Please indicate if you would like your own packaging to be returned to you (except cardboard packaging).

Address for the submission

Please send your safety devices to be tested carriage paid to:

DEHN SE

Hans-Dehn-Straße 1

92318 Neumarkt

GERMANY

Goods receiving times

Monday–Thursday: 07:00–12:00 and 12:30–15:00

Friday: 07:00–12:00

Framework conditions for periodic inspections

- Due to high demand, the throughput time may vary. If necessary, you can ask the "Order Management, Service" team.

- The test is carried out in accordance with EN 61230

- The price of the periodic inspection depends on the type of device in question.

- You will receive a test report for each passed test, and each successfully tested device will be labelled with a sticker on the device.

- If the test reveals that the device is defective or no longer in line with the current state of the art, you will receive a quotation for the repair or a quotation for a comparable new device in a separate letter.

- Third-party devices can be tested but not repaired.

- The return shipment is based on the concluded freight agreement, CPT agreed place of receipt (INCOTERMS 2020), including packaging. The freight costs are based on the actual return weight.

Contact for questions and orders

Please contact our team "Order Management, Service" (DEHN SE "Periodic Inspection Service").

- Phone: +49 9181 906 -1780

- Fax: +49 9181 906 -1215

- Email: [email protected]

Downloads

Testing portable earthing and short-circuiting devices

Our services

We can provide support for your project from the planning to the implementation and beyond. Take advantage of our wide range of practical tools and services.

Did you know...?

Our high-voltage test field is unique worldwide!

Thousands of periodic inspections have been carried out annually at the DEHN high-voltage test facility since 1993. In 2021, the test facility was fundamentally revamped. A unique frequency converter and an interactive voice assistant make the DEHN test facility unique worldwide. The modernisation of the emergency-stop and safety-circuit control system brings the test facility up to a high level in terms of occupational and plant safety.