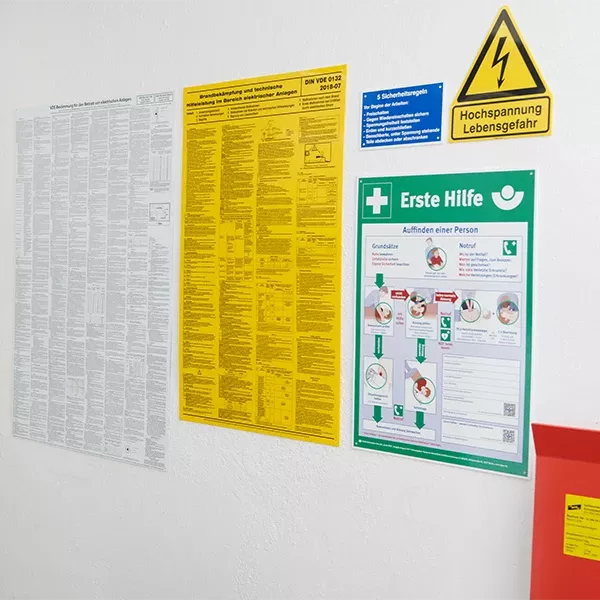

The 5 safety rules of electrical engineering

Working in and around electrical installations can be life-threatening. That is why there are five safety rules that every electrician should know and follow. Whether testing electrical systems or carrying out installation and maintenance work: the five safety rules set out a clear procedure for working in disconnected areas or in the vicinity of live areas. Your compliance protects human life.

This is where the 5 safety rules come into play

The five safety rules for handling electrical energy are applied across various sectors, whether in the field of distribution network operators, industry, power suppliers, photovoltaics, rail, e-mobility and more. Put simply: wherever energy is generated, consumed or distributed, you will also encounter life-saving measures.

The exact areas of the installation that fall under the compliance obligation and what other protective measures need to be taken are determined in the course of the risk assessment.

Enable your employees to apply the five safety rules correctly and ensure that they are reliably protected. We will support you with our products, our services and our expertise.

Safely standard-compliant

Our solutions and products are standard-compliant and meet the requirements of the standard DIN EN 50110-1 that applies across Europe.

Our services

We provide you with a wide range of services that meet the requirements of the five safety rules. This will give you an overview.

Use our practical configurator and put together the earthing and short-circuiting products you need to suit your requirements.

On request, we can clean your medium or low-voltage switchgear for you and help you measure and install insulating protective shutters.

We will regularly test your safety devices in our high-voltage test laboratory in accordance with the acknowledged rules of technology. Your device will receive a label and a test report for documentation purposes.

Let our specialists assess the arc fault risk, evaluate existing protective measures and give you state-of-the-art recommendations.