Protection measures against arc faults

with concept

An arc fault is a rare phenomenon, but a serious hazard. It occurs as an electrical gas discharge due to a technical defect, maloperation, impurities or foreign objects in the system.

Therefore, you should plan your arc fault protection holistically for optimum protection. With the right measures, you will ensure the safety of your employees, optimise the fire protection of your electrical system and ensure that it runs reliably.

Safe when it matters most.

Assess the hazard, minimize the risk

Regardless of whether you want to expand your protection concept with additional measures or develop a new concept. From legal bases to documentation – think holistically for the best possible protection against arc faults.

Your path to all-round protection: DEHN supports you in the planning and realisation of your individual concept. Just contact us and we will work together to develop the right protection solution for you.

Good to know:

The protection against arc faults implemented with DEHNshort significantly exceeds the requirements of test criteria from DIN EN 61439-2, suppl. 1 (IEC TR 61641 Ed. 3 from 2014).

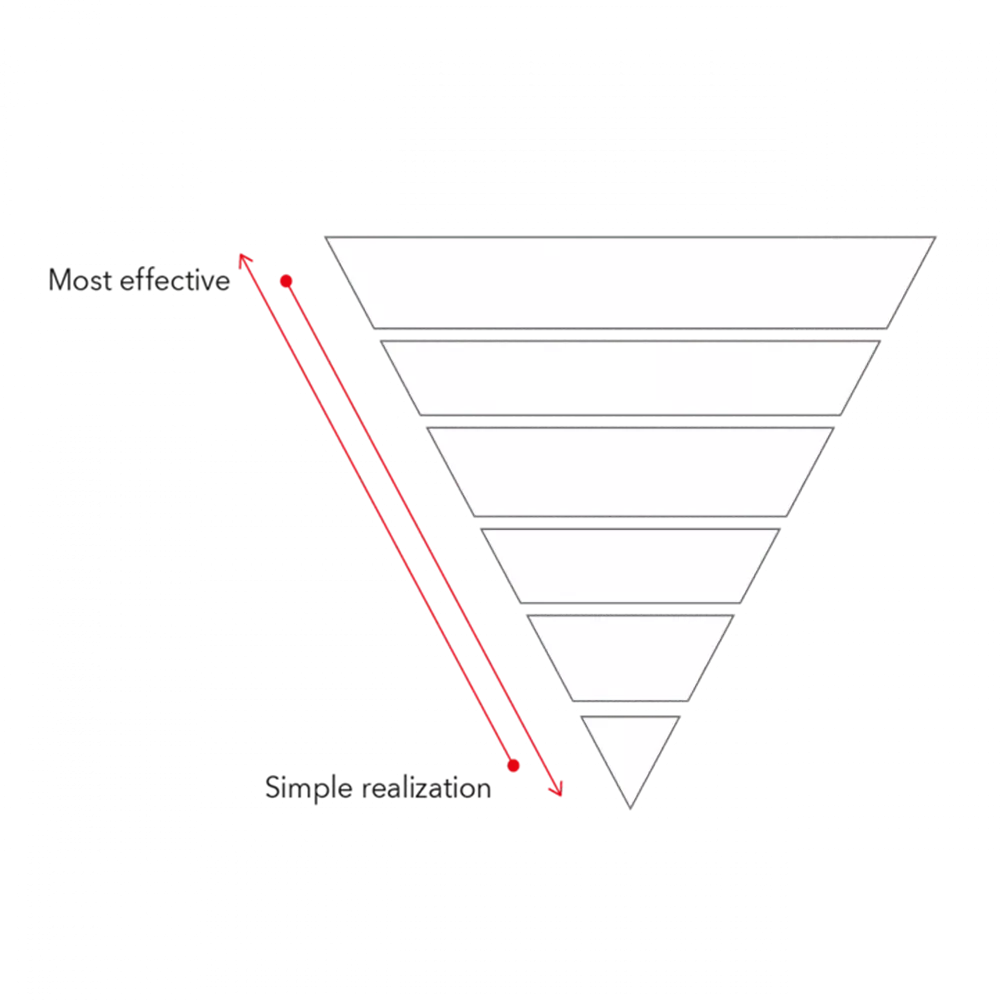

Follow the Hierarchy of Risk Control

As a general rule, hazards are always eliminated at their source. If this does not suffice, further preventive measures can be taken as per the hierarchy of risk control in accordance with NFPA 70 E.

- Elimination e.g. disconnect all electrical equipment completely

- Substitution e.g. internal arc fault mitigation system (IAMS)

- Engineering controls e.g. adjustment of circuit breaker settings

- Awareness e.g. arc flash labelling

- Administrative controls e.g. planned work procedures

- PPE e.g. arc-rated PPE

We will be happy to clear these up in person.

Technical protection measures

Organisational protection measures

Where do arc faults occur?

An arc fault is an unwanted electric arc or spark discharge that occurs between two electrically charged conductors or between a conductor and a conductive material. Arc faults can occur in a variety of electrical systems and equipment, especially switchgear. Electric arcs can generate high temperatures, cause fires and endanger human lives.

However, arc faults are not only a threat to your team. They also have a negative effect on system availability and endanger the permanent electrical power supply. A fault in the switchgear can quickly lead to massive damage, standstills and high losses.

How does an arc fault occur?

An arc fault is created when an electric arc occurs in an uncontrolled manner and in a place where it is not intended. More specifically, interruption or damage to cables, dirt or moisture, poor connections or loose cables and short circuits can result in a major arc faults.

Another cause that should not be underestimated is human error – for example, by dropping tools, live working on supposedly isolated equipment or using unsuitable measuring devices.

How can I protect my team and myself?

Persons working on or in the vicinity of live electrical equipment are, in principle, exposed to hazards associated with arc faults.

An appropriately comprehensive and detailed risk assessment is always the first step in the design of protection concepts. This is also a matter of proportionality and of effective measures. Whenever personal protective equipment is no longer suitable, technical measures are taken.

Choosing suitable personal protective equipment with protective clothing, head and face protection and hand protection against the thermal effects of an arc fault is a fundamental element in protecting your team.

FAQs

This is the electrical energy that is expected in the event of an electric arc at a work location, for example on a switchgear assembly. In addition to the nominal voltage and the short-circuit current, the tripping time of a surge protective device is also used to calculate this energy.

The protection level describes up to which arc energy the personal protective equipment offers protection against the thermal effects of an arc fault. The working distance, the test energy level (protection class) of the PPE against arc faults and the system geometry are used to calculate this energy.

This protection level must always be higher than the arc energy to be anticipated at the work location.

Personal protective equipment against the thermal effects of an electric fault arcs is divided into two categories: Arc fault protection classes 1 and 2. The classes differ in terms of arc energy and incident energy.

For some companies in Germany, two procedures are relevant due to international parent companies. The "open arc test" and "box test" have established themselves worldwide. Clothing tested with the "open arc test" is classified according to the so-called arc thermal performance value (ATPV, in cal/cm²) or the energy incident limit (ELIM, in cal/cm²). In the box test, there are the two protection classes: arc protection class (APC) 1 and 2.

Both methods assume a distance of 300 mm from the source of the arc fault.

The need for and the protection class of personal protective equipment against arc faults is usually determined by the result of a risk assessment.

The following arcing classes are defined in DIN EN 61439-2, suppl. 1:

- A: Minimum protection of people requirements for low-voltage switchgear

- B: Minimum availability requirements, including Class A.

- C: Minimum requirements for continued operation of the switchgear, including classes A and B

Downloads

Counteracting arc faults in electrical systems

Safe energy for industry

Safe when it matters most.

Protect people and systems against arc faults